Update Note, June 2019: Some sources, several legal briefs, and even a footnote in a West Virginia Supreme Court decision have cited this web page for the good aspects of horizontal drilling into shale formations. While we appreciate acknowledging our expertise by citing to us, to quote only what we say about the good aspects of horizontal shale drilling is not entirely accurate, taking our words out of context, and could mislead the reader about the position of WVSORO. Even conventional vertical shale drilling, with its exponentially increased water usage etc., puts more burden on the surface than conventional drilling into sandstones, and that is not good. And, in particular, drilling multiple horizontal wells from one well pad concentrates much if not most of the increased surface disturbance in one place — frequently on just one surface owner, and that is bad for those surface owners. (Fortunately a West Virginia Supreme Court decision has now affirmed what we always believed to be the law — that the surface owner’s agreement must be obtained before using the surface to drill horizontally into mineral tracts that do not underlie the surface owner’s property.) So there are bad, and not just good, aspects to horizontal shale drilling. Our explanation of the good aspects should not be used without noting that we also believe there are bad aspects of horizontal shale drilling.

Note also that the forced well spacing (sometimes called “forced pooling”) that is talked about below on this web page and that was proposed in the Legislature over the years in various versions that favored the industry eventually evolved into a “cotenancy” statute that did pass. We have a new separate web page on that.

Finally note that the original of this web page was drafted in 2012 when the industry was evolving form drilling vertical to horizontal shale wells. Since then vertical Marcellus Shale wells are only rarely being drilled.

Legislation for forced unitization/pooling for drilling horizontal gas wells is ONLY a good idea IF: [Updated 6/24/2015]

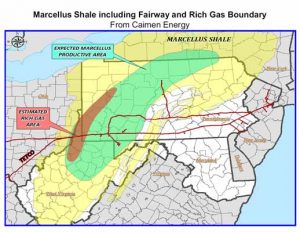

The Marcellus Shale is the newest “play” in gas drilling in West Virginia and other states in the East. It is different from other plays in that it produces much more gas, and is under much more area (as explained below) than previous plays. It could be the biggest play in West Virginia’s history. But it has much more adverse effect on surface land owners and others in West Virginia for two reasons. First, shale wells are drilled much closer together, and are therefore more densely numerous on the surface, than traditional plays in “sands”. Second, the new drilling and fracturing techniques that have for the first time made it possible to economically produce gas from the Marcellus Shale take up much more land and use much more water for “fracturing” the gas bearing formation. Instead of a well site with a typical drilling rig and a single drilling pit on 1.5 to 3 acres (plus a couple tractor trailer loads of water for the “fracture” process), a Marcellus Shale vertical well takes a bigger drilling rig, a bigger drilling pit, and in addition an impoundment pond the size of an Olympic swimming pool to hold 600,000 to 1 Million gallons of water for the fracturing process – and many more than 100 tractor trailer loads of water and sand. (And many are concerned about what happens to the 40 to 60% of that frac water that flows back to the surface which contains chemicals added to it by the driller and that come back up with it from under the ground.) Below is an aerial photograph of a vertical Marcellus Shale gas well drilled in Upshur County, West Virginia, in 2008 (except that an extra pit for capturing the flow back water is not included in the picture).

Until now, almost all gas wells drilled in the East have been drilled vertically, like the one above. The driller sets up a drilling rig on a well site directly above the place where he wants to penetrate the gas bearing formation. He drills straight down until he drills though the gas bearing formation, which in the case of the Marcellus Shale is up to 100 feet thick in West Virginia. He cements production pipe into the gas bearing formation. He puts holes out of the production pipe into the gas bearing formation. He fractures the rock in the area around the 100-foot vertical well bore so the gas will flow out of the formation faster. And he pipes that gas to the surface and to market. This process is illustrated on the right side of the illustration below. Here is a more detailed slide show of how vertical gas well drilling is done.

Until now, almost all gas wells drilled in the East have been drilled vertically, like the one above. The driller sets up a drilling rig on a well site directly above the place where he wants to penetrate the gas bearing formation. He drills straight down until he drills though the gas bearing formation, which in the case of the Marcellus Shale is up to 100 feet thick in West Virginia. He cements production pipe into the gas bearing formation. He puts holes out of the production pipe into the gas bearing formation. He fractures the rock in the area around the 100-foot vertical well bore so the gas will flow out of the formation faster. And he pipes that gas to the surface and to market. This process is illustrated on the right side of the illustration below. Here is a more detailed slide show of how vertical gas well drilling is done.

There are two kinds of “directional”gas well drilling that can be done instead of vertical drilling. The first one is not the one we are talking about here. The first one is the kind done mostly from offshore drilling platforms. It is “slant drilling”. As soon as the drilling bit enters the earth, the driller slants it at a slight angle off vertical. By the time it reaches the target formation thousands of feet down, it is hundreds or maybe even thousands of feet away horizontally from where it started at the surface. By drilling multiple wells in all directions from the same drilling platform, a large area of the deep oil or gas bearing formation can be punctured with near vertical well bores for producing oil or gas. This “slant drilling” is still rare in the East.

There are two kinds of “directional”gas well drilling that can be done instead of vertical drilling. The first one is not the one we are talking about here. The first one is the kind done mostly from offshore drilling platforms. It is “slant drilling”. As soon as the drilling bit enters the earth, the driller slants it at a slight angle off vertical. By the time it reaches the target formation thousands of feet down, it is hundreds or maybe even thousands of feet away horizontally from where it started at the surface. By drilling multiple wells in all directions from the same drilling platform, a large area of the deep oil or gas bearing formation can be punctured with near vertical well bores for producing oil or gas. This “slant drilling” is still rare in the East.

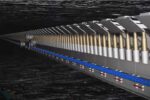

The second kind of directional drilling is “horizontal” drilling. It is what is being done, and should be done even more, in the East. It is illustrated on the left side of the image above. The driller drills down vertically until near the top of the gas bearing formation, then new technology allows the driller to bend the well bore sideways so that it is horizontal by the time it penetrates the gas bearing formation. Using pressure from the downward wight of the horizontal drilling pipe the driller can drill 4000 or 5000 feet sideways, and maybe more, through the Marcellus Shale. Developing techniques allow the driller to fracture the horizontal well bore in stages all along its 4000 feet of length – as opposed to fracturing only the 100 feet that a vertical well bore runs down through the Marcellus Shale here. As you can see in the illustration above, it would take four or more vertical wells to drill, fracture and produce the area of the gas bearing formation that can be produced by only one horizontal well. (To see an illustration of horizontal drilling go to our slide show on vertical drilling and click on the link at the bottom of the introductory page.)

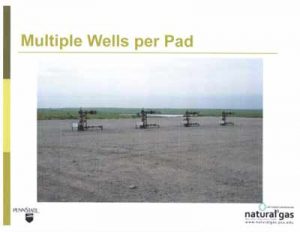

Even newer techniques allow the driller to drill 4 or 6 or even 8 horizontal wells from only one well pad/site! See the image below showing only 4 wells on one site.

Having 6 or 8 horizontal wells drilled from one pad taking the place of 20 o4 24 vertical wells each on their own well pad/site is a HUGE improvement for surface owners! As illustrated below, one horizontal well pad/site (see the yellow square below) with six wells horizontal wells drilled from it (see the yellow lines below) can take the place of 24 vertical wells pads/sites (the purple squares below).

Having 6 or 8 horizontal wells drilled from one pad taking the place of 20 o4 24 vertical wells each on their own well pad/site is a HUGE improvement for surface owners! As illustrated below, one horizontal well pad/site (see the yellow square below) with six wells horizontal wells drilled from it (see the yellow lines below) can take the place of 24 vertical wells pads/sites (the purple squares below).

So with horizontal drilling there is 1 well pad/site with one access road and one drilling pit and one frac water impoundment pond instead of 24 five-acre, vertical well pads/sites, and 24 access roads and 24 drilling pits and multiple frac water impoundments. (Note that the vertical wells in this illustration are spaced 1000 feet apart. Most Marcellus Shale wells in West Virginia are being spaced 1500 feet apart. So these 6 horizontal wells might not replace quite as many vertical wells as the image illustrates. But the point is the same. And the drillers are now drilling 8 wells from one well pad instead of the 6 in the illustration!)

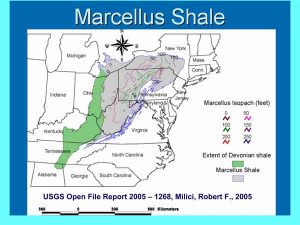

What does this mean for surface owners? Earlier new gas well “plays” discovered in West Virginia were as large as one county, or maybe several counties. Also, almost all of the gas well drilling in West Virginia was west of I-79. The Marcellus Shale is under almost all of West Virginia, though it is better in some places than others.

The typical Marcellus Shale well pad/site is 5 acres. If vertical wells are drilled on 1500 foot spacing, which is one well for every 40 acres. So almost all of West Virginia could be covered by a 5 acre well site every 40 acres. Below is a picture taken in the Catskills. The grey area in the left foreground is a gravel pit and not a well site. But the rest of the cleared areas are 5 acre Marcellus Shale well sites drilled on 40 acre spacing.

The typical Marcellus Shale well pad/site is 5 acres. If vertical wells are drilled on 1500 foot spacing, which is one well for every 40 acres. So almost all of West Virginia could be covered by a 5 acre well site every 40 acres. Below is a picture taken in the Catskills. The grey area in the left foreground is a gravel pit and not a well site. But the rest of the cleared areas are 5 acre Marcellus Shale well sites drilled on 40 acre spacing.

The image below is an aerial view of gas well sites drilled on 40 acre spacing in the Jonas basin in the West.

The image below is an aerial view of gas well sites drilled on 40 acre spacing in the Jonas basin in the West.

Does ANYONE think this is a good idea for West Virginia!

Does ANYONE think this is a good idea for West Virginia!

Not only is horizontal drilling of multiple Marcellus Shale gas wells from centralized well pads/sites better for surface owners, it is better for lots of other people and interests:

See Update Note, June, 2019, at top of web page

•It is less risk to ground water if there are only 6 penetrations in one place from the 6 or 8 wells on the centralized pad instead of 24 all over the place.

•It lessens the dangers of other environmental concerns because there is less forest fragmentation, less inevitable steam siltation from more access roads (and horizontal well access roads tend to be better constructed and maintained than vertical well access roads) etc. etc.

•It is better for coal owners and coal companies and coal miners. This is because the horizontal well driller goes through the coal seams while the well bore is still being drilled vertically. So 6 or 8 well bores are drilled through one spot in the horizontal coal seam, rather than drilling 24 vertical bores drilled all through the coal seam. Since the well bores are drilled in one spot, there is less risk to the safety of miners of running into one as they mine through the coal seam. Because coal companies have to leave a circle of unmined coal around every gas well bore in order to protect miners, having 24 well bores spread out all through the coal seam would “sterilize” large quantities of coal from being mined.

•Investors in oil and gas drilling probably also are benefitted. Although the initial capital cost of a horizontal well is greater, they get out more gas faster and cheaper than vertical wells and so save production costs in the long run.

Why aren’t all Marcellus Shale wells drilled this way?

First, at least one vertical well needs to be drilled in an area to be able to tell exactly how deep and how rich the Marcellus Shale formation is.

Second, the driller has to have maybe 640 acres of contiguous mineral land for horizontal drilling of multiple wells from a central well pad to work. Very often that 640 acres of minerals the driller needs is made up of smaller tracts owned separately by different individuals. If one or more of them does not agree (or if a different driller holding the lease on one of them holds the horizontal driller hostage for an unreasonable payment) the driller cannot take the horizontal well bore through the gas bearing formation of the owner who is holding out. The hold out can spoil the accumulation of the amount of land needed in order for horizontal drilling from a central well pad to work. (The driller can drill the horizontal well bore right next to and along the boundary of the hold out and drain the gas out from under the hold out as long as the well bore does not go under them — and the hold out will not get paid.)

There are laws in place in most other states, but only for some gas producing formations in West Virginia, that can solve this problem. We call it “forced well spacing and royalty sharing”, but the statutes call it “forced pooling and unitization”. Under these laws, if a driller accumulates the leases/the right to drill for a certain percentage of the 640 acres, then he can “force” the rest to allow drilling under (not on) their land. In return the “forced” owner gets their share of the royalties. And if they want, they can invest in the drilling and get a share of the working interest in the well. West Virginia ought to extend its laws for forced well spacing and royalty sharing to horizontal Marcellus Shale wells that are drilled from central well pads/sites. See our slide show on why well spacing and royalty sharing ought to be adopted for all gas wells in all formations in West Virginia!

Third, some small drillers claim they cannot raise the money to drill the more expensive horizontal wells. We think these small drillers should get some benefit of joining their properties with other larger drillers who can afford to drill horizontal wells, but they should not be able to obstruct horizontal drilling and forced well spacing.

Fourth, some areas may not have the geology for the Marcellus Shale horizontal wells. If that is true, allowances should be made for that.

The bad thing about horizontal drilling is that, while there is less total surface damage, it is all concentrated on one surface owner. WVSORO believes that the law does not permit drillers to do that without obtaining permission (in writing) from that one surface owner, whether the surface owner does or does not own the minerals. See our web page on that. And if the surface owner does agree to allow the centralized pad to be drilled on their land, then the surface owner should insist on environmental and surface protections that other drillers have agreed to, in particular a liner covering the pad should be used so that spills do not leach down into groundwater. And surface owners, particularly those who do not own the minerals and so will not be getting any royalty, should be compensated for the use of their surface based not on what the surface was worth to them before the driller showed up, but based on what the use of their surface is worth to the driller! It costs $3 to $7 Million to drill each well on a pad, and they are drilling multiple wells. If you are a surface owner who also owns the minerals and will be getting royalty, you should ask for $25,000 per well. That is only 8/100ths to 4/100ths of 1% of the cost of drilling each well. If you do not own the minerals, and if you want to let them drill, and if you get paid less than that, you are being played. Unfortunately you will probably have to hire a lawyer to get that because the State will grant them their permit if it has the environmental protections the State wants, and leave it to you to protect your surface ownership rights.

So:

If the Marcellus Shale is going to be drilled, the best thing for almost everyone is for Marcellus Shale wells to be drilled horizontally from centralized well pads/sites. Ideally the West Virginia Legislature would pass fair laws authorizing “forced” well spacing (“pooling and unitization”) for all wells in the Marcellus Shale and encouraging these horizontal Marcellus Shale wells to be drilled from centralized well pads/sites. However, WVSORO, has learned the hard way that any such legislation that the Legislature would pass would only give the drillers what they want out of such legislation, and would not protect surface owners or other mineral owners. See our web page on this subject. So we and you should oppose forced pooling legislation as a taking of surface owner’s rights.

If you are a surface owner, and if someone wants to put a well site for drilling horizontal wells on you and you do not want that massive disturbance on you, or if they will not pay you what it is worth to them to use your surface, then go to our web page on how to stop them, and send the letter recommended there and contact a lawyer now. The same applies if you own surface and minerals, but you or your predecessors have already signed a lease that specifically allows for the use of your surface to drill horizontally into neighboring mineral tracts. (If you have signed a lease or an amendment with a pooling or unitization agreement, the driller will say that this gives them permission, but we still say that the new massive well sites are not authorized because they were not in the contemplation of the parties as explained on the web page referred to above.)

If you are a surface and mineral owners and a driller wants you to sign an amendment to the lease to make pooling and unitization possible, you should read our advice on that.