After the tubing and un-cemented casing has been pulled out of the well, the plugger starts to actually plug up the bore hole headnidg up to teh surface plus any casing that is cemented into the bore hole.

After the tubing and un-cemented casing has been pulled out of the well, the plugger starts to actually plug up the bore hole headnidg up to teh surface plus any casing that is cemented into the bore hole.

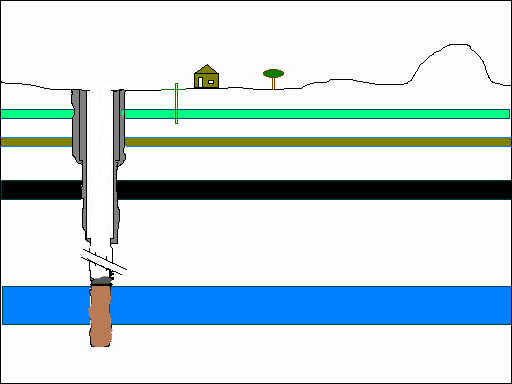

The first thing the plugger does to start actually plugging the hole is to “kill” the well — in other words, stop the gas from coming out of the formation and up the borehole so that the rest of the work can be done. If gas was still coming out of the formation as plugging occurred above formation, that gast could make bubbles in the cement bridge before it hardens etc. Generally this “killing” is done by putting drilling “mud” down at the bottom. The weight of the specially formulated drilling mud exceeds the pressure of the gas and stops the gas from flowing out of the target formation. The drilling mud is shown in brown on this drawing. (It looks grey in future drawings – sorry.)

After the mud is in, the plugger puts down a layer of cement over it. This is the first cement “bridge”, this one wall to wall of the borehole, across the open, un-cased borehole. Its purpose is to clock the gas from moving upwards. It is right above or even perhaps reaches down into the formation that produced the gas. This is shown as a thin grey layer right above the brown mud in this slide. In reality this cement layer of the plug could be 100 feet thick vertically. It is a special cement that in theory does not shrink as it hardens, though it may be that it just shrinks less than most other cements. It may have special additives to do the job best.