Slide

21 posts found, showing 20 per page

Previous Next

Summary.

Slide WVSORO May 5, 2022

So plugging is not capping. Old oil and gas wells need plugged. This needs done properly or serious problems can occur. And it needs State and surface owner and coal owner and mineral owner oversight to be sure that pluggers avoid the temptation to save money and get to the next job. It needs oversight while it is happening so that they do not save money by cutting corners that cannot be seen once the job is finished. More

Slide WVSORO May 5, 2022

So plugging is not capping. Old oil and gas wells need plugged. This needs done properly or serious problems can occur. And it needs State and surface owner and coal owner and mineral owner oversight to be sure that pluggers avoid the temptation to save money and get to the next job. It needs oversight while it is happening so that they do not save money by cutting corners that cannot be seen once the job is finished. More

Bad plug job results.

Slide WVSORO May 5, 2022

So again, numerous problems can arise from improper plugging. This is an illustration of some of them. The methane can leak up into coal formations, into gas and other porous or permeable formations between the producing formation and the coal. More

Slide WVSORO May 5, 2022

So again, numerous problems can arise from improper plugging. This is an illustration of some of them. The methane can leak up into coal formations, into gas and other porous or permeable formations between the producing formation and the coal. More

Bad plug job.

Slide WVSORO May 5, 2022

Again, our purpose #3 for this slide show, is to illustrate the concern is that if a plugging company is not well overseen, it may take shortcuts to save money. This illustration shows that the tubing was pulled, but the production casing was not pulled -- only cut off a few tens of feet below ground. More

Slide WVSORO May 5, 2022

Again, our purpose #3 for this slide show, is to illustrate the concern is that if a plugging company is not well overseen, it may take shortcuts to save money. This illustration shows that the tubing was pulled, but the production casing was not pulled -- only cut off a few tens of feet below ground. More

API number on monument to plugged well.

Slide WVSORO May 5, 2022

The API number required to be on the monument was done with welding in this case. Note the grey cement from teh surface cement job at the bottom of the monument. More

Slide WVSORO May 5, 2022

The API number required to be on the monument was done with welding in this case. Note the grey cement from teh surface cement job at the bottom of the monument. More

Surface reclaimed and mistakes hidden.

Slide WVSORO May 5, 2022

After the well is plugged and the monument set, the area disturbed is to be "reclaimed" to avoid soil erosion and sedimentation. (Surface owners, particularly farmers, may want to insist on certain seed types.) More

Slide WVSORO May 5, 2022

After the well is plugged and the monument set, the area disturbed is to be "reclaimed" to avoid soil erosion and sedimentation. (Surface owners, particularly farmers, may want to insist on certain seed types.) More

Isolating other gas bearing formations.

Slide WVSORO May 5, 2022

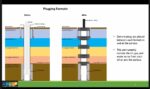

This is a different illustration from another source of a well before and after plugging. It does not show a coal seam (like there almost always is in West Virginia) but it does show multiple oil and gas formations that are likely here in West Virginia. More

Slide WVSORO May 5, 2022

This is a different illustration from another source of a well before and after plugging. It does not show a coal seam (like there almost always is in West Virginia) but it does show multiple oil and gas formations that are likely here in West Virginia. More

Plugged well overview drawing.

Slide WVSORO May 5, 2022

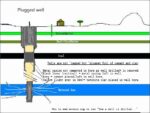

This drawing summarizes this simplified plugging explanation. The actual details of the plugging for an individual well will be in the plugging permit application and its approval which are, at least since 1929 or so, on record with the Department of Environmental Protection, Office of Oil and Gas, under the well's API number. More

Slide WVSORO May 5, 2022

This drawing summarizes this simplified plugging explanation. The actual details of the plugging for an individual well will be in the plugging permit application and its approval which are, at least since 1929 or so, on record with the Department of Environmental Protection, Office of Oil and Gas, under the well's API number. More

Cementing to surface.

Slide WVSORO May 5, 2022

Cement is then again placed in the borehole (and inside the surface casing pipe that was placed at the top of the hole and cemented in during drilling) all the way to the surface. At the top it is required that a "monument" be placed at the surface to mark the well's plugged location. Usually this is a four-foot metal pipe stuck in the surface cement job and itself is filled with cement. More

Slide WVSORO May 5, 2022

Cement is then again placed in the borehole (and inside the surface casing pipe that was placed at the top of the hole and cemented in during drilling) all the way to the surface. At the top it is required that a "monument" be placed at the surface to mark the well's plugged location. Usually this is a four-foot metal pipe stuck in the surface cement job and itself is filled with cement. More

One more clay layer.

Slide WVSORO May 5, 2022

Again bentonite clay is placed above the cement bridge that is placed through the coal seam (though in some circumstances cement may be continued from the bottom of the coal all the way to the surface). More

Slide WVSORO May 5, 2022

Again bentonite clay is placed above the cement bridge that is placed through the coal seam (though in some circumstances cement may be continued from the bottom of the coal all the way to the surface). More

Dealing with the coal seam.

Slide WVSORO May 5, 2022

Coal seams also need to be isolated from any gas pressure or invasion. For one thing, coal seams have a form of cracks called cleats that can allow the gas to travel broadly in the horizontal plane and cause problems anywhere the coal seam is breached or even if it comes to the surface Also, increasing the methane in coal seams makes them harder to mine. And finally, and most importantly, it would be very dangerous to miners for a continuous mining machine to cut through a gas well that was not properly plugged and leak poisonous and explosive gas into the coal mine! More

Slide WVSORO May 5, 2022

Coal seams also need to be isolated from any gas pressure or invasion. For one thing, coal seams have a form of cracks called cleats that can allow the gas to travel broadly in the horizontal plane and cause problems anywhere the coal seam is breached or even if it comes to the surface Also, increasing the methane in coal seams makes them harder to mine. And finally, and most importantly, it would be very dangerous to miners for a continuous mining machine to cut through a gas well that was not properly plugged and leak poisonous and explosive gas into the coal mine! More

Using clay and cement to plug un-cemented, now un-cased, bore hole.

Slide WVSORO May 5, 2022

A special form of clay or other material is used for the next layer of plugging the borehole. This clay is often bentonite clay, a clay that expands as it soaks up water. It is very similar to kitty litter. It has other additives sometimes to do the best job. Probably because it is cheaper than cementing all the way to the top, most of the vertical height of the plug in the borehole is clay as we shall see in the next slides. It is shown as yellow in these slides. More

Slide WVSORO May 5, 2022

A special form of clay or other material is used for the next layer of plugging the borehole. This clay is often bentonite clay, a clay that expands as it soaks up water. It is very similar to kitty litter. It has other additives sometimes to do the best job. Probably because it is cheaper than cementing all the way to the top, most of the vertical height of the plug in the borehole is clay as we shall see in the next slides. It is shown as yellow in these slides. More

Killing the production formation and cementing above it.

Slide WVSORO May 5, 2022

After the tubing and un-cemented casing has been pulled out of the well, the plugger starts to actually plug up the bore hole headnidg up to teh surface plus any casing that is cemented into the bore hole. More

Slide WVSORO May 5, 2022

After the tubing and un-cemented casing has been pulled out of the well, the plugger starts to actually plug up the bore hole headnidg up to teh surface plus any casing that is cemented into the bore hole. More

UN-cemented casing has been pulled.

Slide WVSORO May 5, 2022

This graphic shows that the casing pipe that is not cemented into the well borehole has been cut at the bottom and pulled out the same way the tubing was. The casing pipe that has been cemented into the borehole cannot be removed (except sometimes later for coal mining -- see later slide). It is hoped that the cementing of the cemented casing pipe that is left in at the time of plugging was done right when the well was drilled and cemented. More

Slide WVSORO May 5, 2022

This graphic shows that the casing pipe that is not cemented into the well borehole has been cut at the bottom and pulled out the same way the tubing was. The casing pipe that has been cemented into the borehole cannot be removed (except sometimes later for coal mining -- see later slide). It is hoped that the cementing of the cemented casing pipe that is left in at the time of plugging was done right when the well was drilled and cemented. More

Tubing has been pulled and surface facilities removed.

Slide WVSORO May 5, 2022

This drawing shows that the tubing, shown as blue on previous slides, has been pulled out of the well and placed on the flatbed truck in the earlier picture, and the tank and wellhead and other equipment at the surface have been removed. More

Slide WVSORO May 5, 2022

This drawing shows that the tubing, shown as blue on previous slides, has been pulled out of the well and placed on the flatbed truck in the earlier picture, and the tank and wellhead and other equipment at the surface have been removed. More

Tubing that has been pulled from well.

Slide WVSORO May 5, 2022

The plugging has begun. The pressure from the gas-bearing formation (and there is probably not much pressure left) has been "killed" as explained in a futuer slide. The plugger has started pulling out the tubing and loading it onto this flatbed truck to be hauled away and scrapped. The UN-cemented casing will also be pulled from the well and will be placed on this or a similar flat bed trailer and hauled away. More

Slide WVSORO May 5, 2022

The plugging has begun. The pressure from the gas-bearing formation (and there is probably not much pressure left) has been "killed" as explained in a futuer slide. The plugger has started pulling out the tubing and loading it onto this flatbed truck to be hauled away and scrapped. The UN-cemented casing will also be pulled from the well and will be placed on this or a similar flat bed trailer and hauled away. More

Some of the plugging equipment.

Slide WVSORO May 5, 2022

In this picture the time has come to plug the well and, as pictured here, some of the equipment that is needed to plug a well is brought to the site. Facing the camera on the right is a truck pulling a flat bed trailer on which the tubing and casing will be placed and hauled away once it is cut off at the bottom and pulled up out of the well. On the left facing the camera is a tank truck probably carrying water necessary to mix with the clay that is talked about later. More

Slide WVSORO May 5, 2022

In this picture the time has come to plug the well and, as pictured here, some of the equipment that is needed to plug a well is brought to the site. Facing the camera on the right is a truck pulling a flat bed trailer on which the tubing and casing will be placed and hauled away once it is cut off at the bottom and pulled up out of the well. On the left facing the camera is a tank truck probably carrying water necessary to mix with the clay that is talked about later. More

Surface facilities.

Slide WVSORO May 5, 2022

This drawing is simpler and a little more to scale, plus it also shows some of the larger surface features of an active gas well. These surface features/equipment include: The well head and its ipes connected on the top of the casing and tubing. A tank for oil at an oil well or at a gas well sometimes for brine or other liquids that sometimes comes up with the gas from some formations/locations. Some kind of metering/measuring system. More

Slide WVSORO May 5, 2022

This drawing is simpler and a little more to scale, plus it also shows some of the larger surface features of an active gas well. These surface features/equipment include: The well head and its ipes connected on the top of the casing and tubing. A tank for oil at an oil well or at a gas well sometimes for brine or other liquids that sometimes comes up with the gas from some formations/locations. Some kind of metering/measuring system. More

Tubing inside casing.

Slide WVSORO May 4, 2022

In addition to the metal casing pipe, another smaller metal pipe is inserted down to the producing target formation inside the smallest casing pipe. It shows up in blue in this drawing. This smaller pipe is called the "tubing". It is through this tubing pipe that the gas actually flows up to the surface. More

Slide WVSORO May 4, 2022

In addition to the metal casing pipe, another smaller metal pipe is inserted down to the producing target formation inside the smallest casing pipe. It shows up in blue in this drawing. This smaller pipe is called the "tubing". It is through this tubing pipe that the gas actually flows up to the surface. More

Properly drilled, cased, and cemented well before plugging.

Slide WVSORO May 4, 2022

This slide shows a drawing of an oil or gas well after it has been properly drilled and cased/cemented. Several concentric layers of metal casing pipe have been inserted into the well borehole. Usually in West Virginia there is a surface casing pipe, and then inside that a casing pipe down through the coal and then inside that a “production” casing pipe all the way down into the target formation. More

Slide WVSORO May 4, 2022

This slide shows a drawing of an oil or gas well after it has been properly drilled and cased/cemented. Several concentric layers of metal casing pipe have been inserted into the well borehole. Usually in West Virginia there is a surface casing pipe, and then inside that a casing pipe down through the coal and then inside that a “production” casing pipe all the way down into the target formation. More

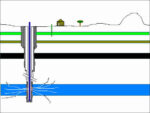

Showing formations originally drilled through.

Slide WVSORO May 4, 2022

Lets start by showing the relevant underground rock layers/formations through which a gas well is drilled in an abbreviated, drawing view. There is the green good ground water formation that needs protected, the brown bad groundwater formation that needs to be kept to itself, the black coal seam that needs protected from gas, and the blue gas-bearing target rock formation/strata from which the driller wants to produce gas. More

Slide WVSORO May 4, 2022

Lets start by showing the relevant underground rock layers/formations through which a gas well is drilled in an abbreviated, drawing view. There is the green good ground water formation that needs protected, the brown bad groundwater formation that needs to be kept to itself, the black coal seam that needs protected from gas, and the blue gas-bearing target rock formation/strata from which the driller wants to produce gas. More

Previous Next