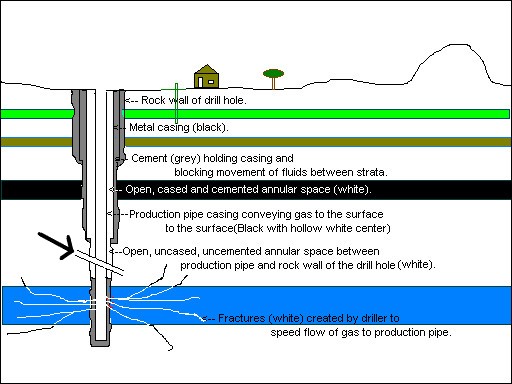

This slide shows a drawing of an oil or gas well after it has been properly drilled and cased/cemented. Several concentric layers of metal casing pipe have been inserted into the well borehole. Usually in West Virginia there is a surface casing pipe, and then inside that a casing pipe down through the coal and then inside that a “production” casing pipe all the way down into the target formation. (Sometimes at the surface, outside the surface casing pipe, there is a larger “conductor” pipe just a few feet down in teh ground before hitting rock formations so that surface earth does not fall down into the hole.)

Some of the metal casing pipes, but not all of those casing pipes, have cement that has been inserted between the outside of the casing pipe and the inside of the rock through which the borehole was drilled (or sometimes the inside of bigger metal casing pipe into which the smaller casing was inserted).

However, a lot of the metal well casing pipe is “un-cemented” — just hanging/standing inside the well borehole or inside a larger casing pipe. In particular, probably several thousand feet of production casing pipe in the well borehole (between the \\’s pointed to by the dark black arrow in the illustration) is un-cemented. There is no cement or anything else between the outside of the production casing pipe and the raw rock of the inside of the borehole. Note that this un-cemented casing pipe between those \\’s can be hundreds or more likely even thousands of feet vertically labeled in this drawing as “Open, un-cased, un-cemented annular space between the production pipe and rock wall of the drill how (white).”

To see how all of the setting of the concentric layers of the casing paper were inserted and some were cemented, as suggested above, go to our slide show “How a Gas Well Is Drilled Down Into the Ground, and What Can Go Wrong“. Many of the things that can go wrong if drilling is not done property and illustrated by that drilling slide show can also go wrong if the plug job is done wrong. For the sake of brevity this plugging slide show will not illustrate all the things that can go wrong, but a view of the drilling slide show will show the same things that can go wrong with a bad plug job.